Green Circular Loom Controller GCL GLC-004 developed for automation of circular weaving machine, and capable of handling the functions required in sophisticated weaving process. Warp and weft break detection facilities are available. Suitable for 4, 6, 8 and 10 shuttle looms. Programmable crush pattern feature and WEFT density can be configured. Inch provision for Operator conveninece while joining WEFT brake and coil change.

Fig. Loom Controller GCL (Model no. GLC-004)

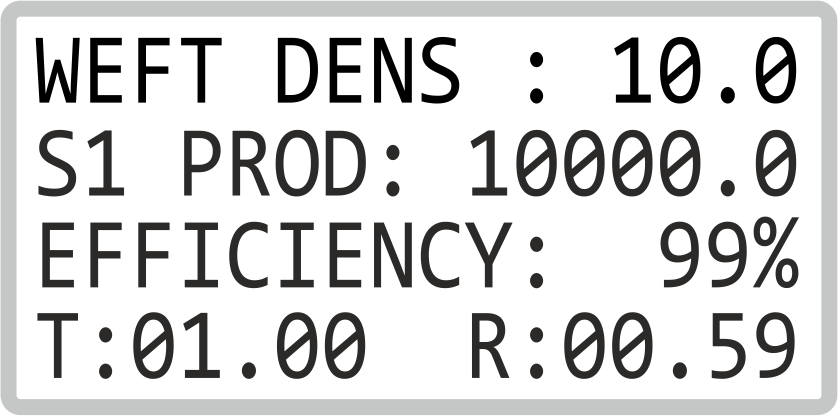

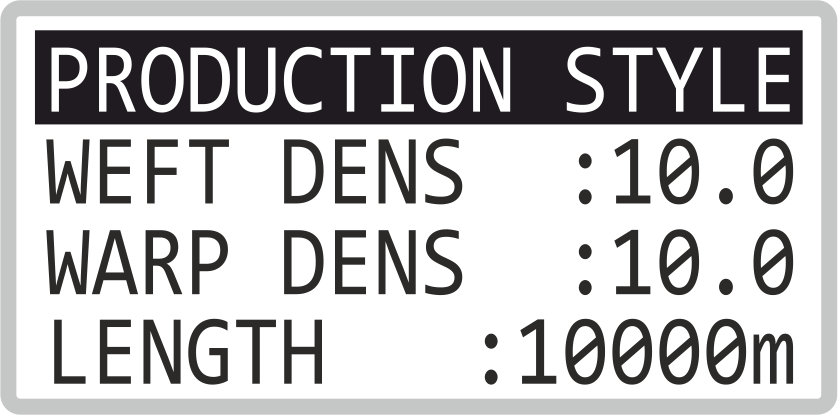

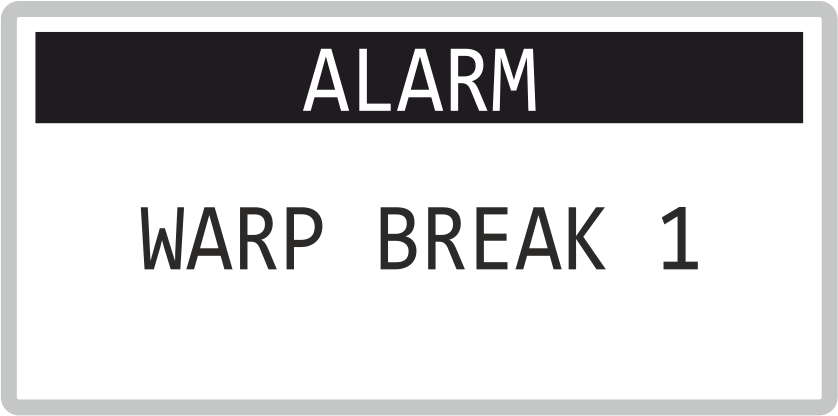

Fig. The above images shows the sample screens from Loom Controller GCL GLC-004

Features

- 128 x 64 Graphical Display

- User configurable Weft Density

- Factory settable

- Number of shuttle

- Main drive shaft encoder PPR

- Take up Roller diameter

- Take up Shaft encoder PPR

- Gear ratio

- Crush pattern editing facility

- Drive communication feature

- Live Run time data monitor window

- Length setting provision

- PPM (Picks per minute) display

- Efficiency Display

- 3 password levels

- Shiftwise Production display

- Warp and Weft brake alarm and logging

Specification

| Model | GCL GLC-004 |

| Display | 128 x 64 Graphical LCD Display |

| LCD Backlight | Yes |

| Digital Input | 16 |

| Digital Output | 6 |

| High Speed Encoder Input | Yes |

| Password | 3 Level |

| User programming | 23 keys and Graphical LCD Display |

| Serial Communication | RS - 485 MODBUS RTU |

| Supply voltage | 24VDC |

| Operating voltage range | +/-10% from the rated voltage |

| Cut-out (L x W) | 205 x 100 mm |

| Dimension ( L x W x D) | 218 x 114 x 48 mm |

| Ambient humidity | 35 to 85% RH |

| Ambient temperature | -10 to 55 c |

| Storage temperature | -25 to 65 c |

| In the pack | Loom Controller, Side clamp, User Manual |